-40%

1650 SQ.FT ECO SOLID TIMBER AIRTIGHT PANEL HOUSE KIT MASS WOOD (CLT) HOME PREFAB

$ 58361.95

- Description

- Size Guide

Description

SOLID WOOD PANEL HOUSE KIT, MODEL # CLT-153,sold exclusively by

ECOHOUSEMART

and custom made to order. It is made of today's most advanced solid wood technology

CROSS-LAMINATED TIMBER PANELS (CLT)

, species - white Spruce.

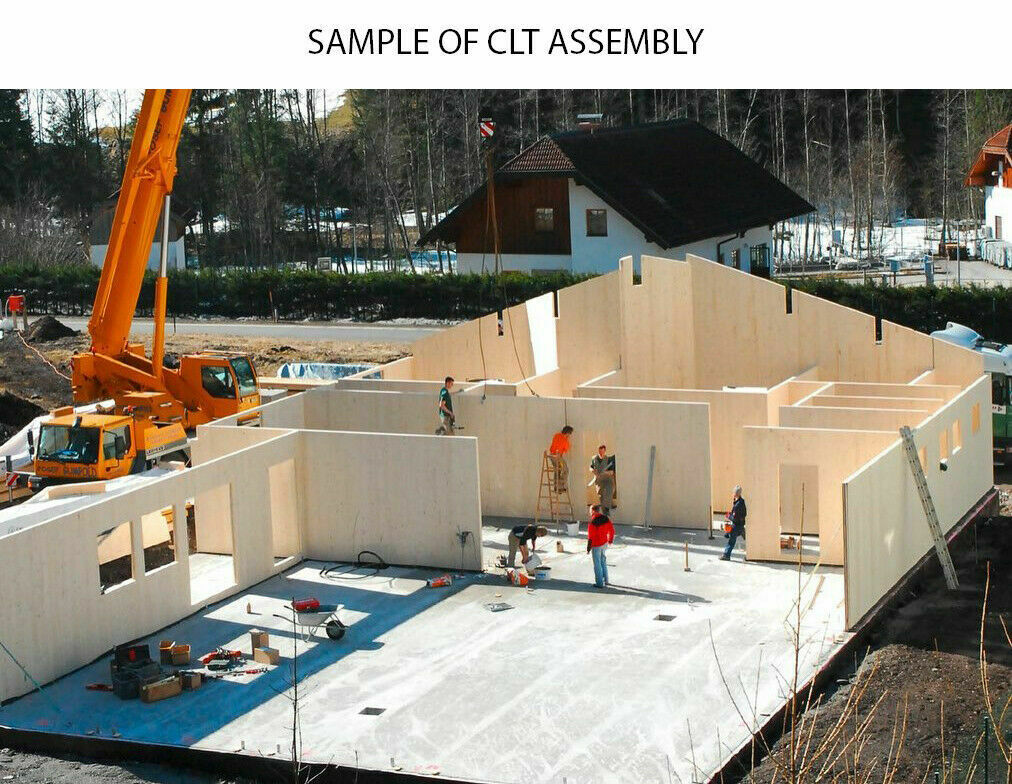

The Solid Cross-Laminated Timber panels (CLT) and the other (described below building materials) are delivered to the construction site for local professional assembly by timber construction companies or construction companies using a boom crane within the shortest possible construction period. CLT wall set is assembled within a few days.

CLT HOUSE BUILDING PHYSICS:

The CLT wall systems are naturally breathable, which, integrated with appropriate mechanical systems, will result in a healthy indoor environment that maximizes occupant comfort and health

Wood mass: comfortable living environment, heat storage in winter, insulation in summer

Visual quality: pleasantly warm wood surfaces, nature in architecture, outstanding constructional properties

Air tightness – or more accurately referred to as convection tightness – is an essential parameter of modern CLT houses and sustainable constructions.

Very good thermal insulation and heat protection

Passive house and low-energy house standards can be optimally achieved

Healthy and comfortable indoor climate, optimal heat storage capacity, and humidity regulation

Recommended in terms of building biology

High fire resistance

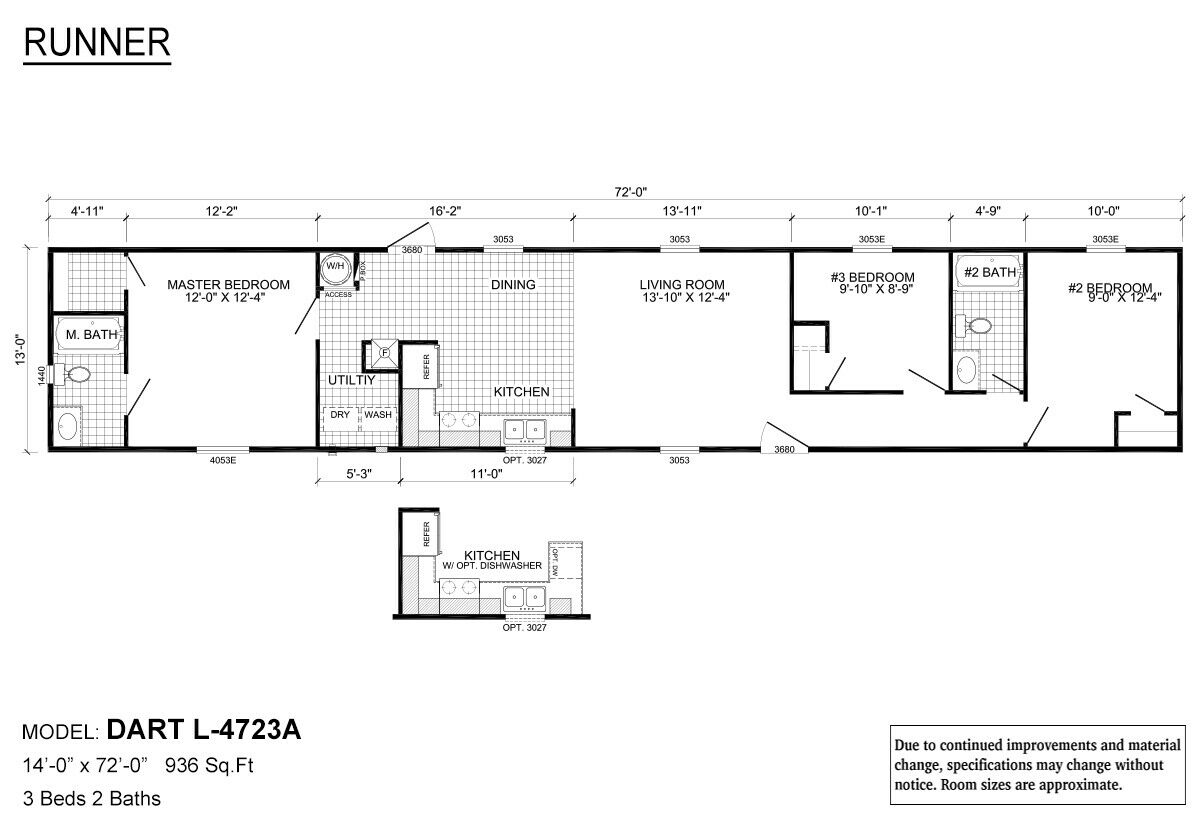

MODEL: CLT-153

THIS HOUSE KIT IS NOT BUILT YET AND WILL BE CUSTOM ORDERED ACCORDING TO YOUR REQUIREMENTS.

A genuine

ECOHOUSEMART

CLT house provides a healthy living environment, high indoor air quality, and a warm, stress-reducing atmosphere. It's an ecological home that quite literally takes good care of the people within its walls.

PRODUCT OVERVIEW OF THE CLT-153

PREFAB KIT:

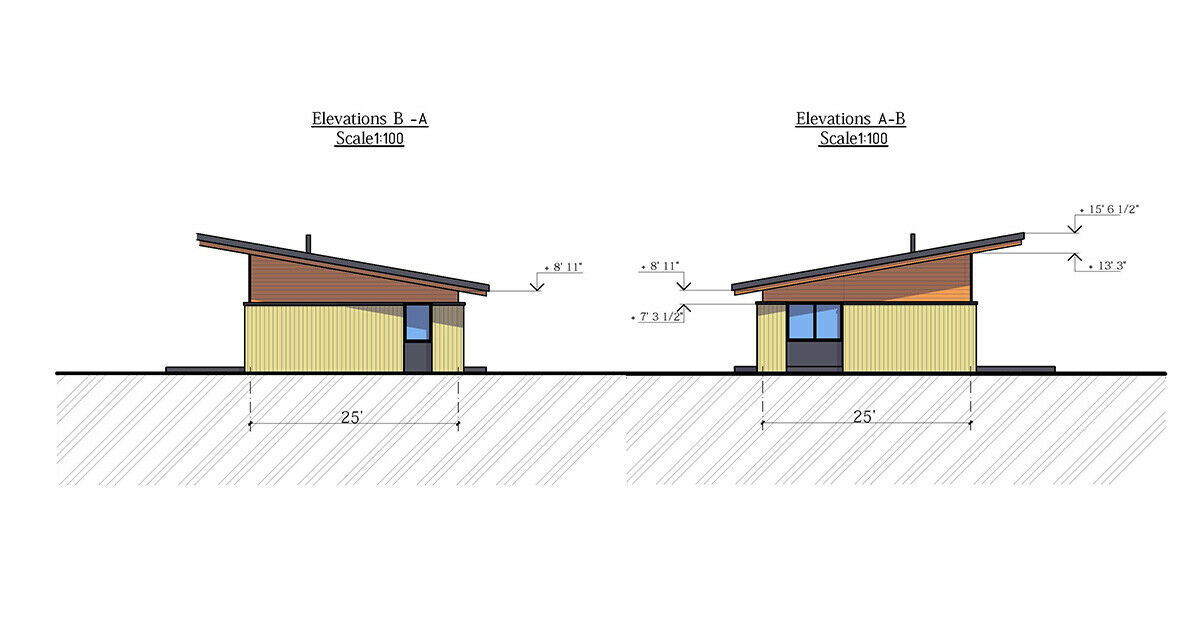

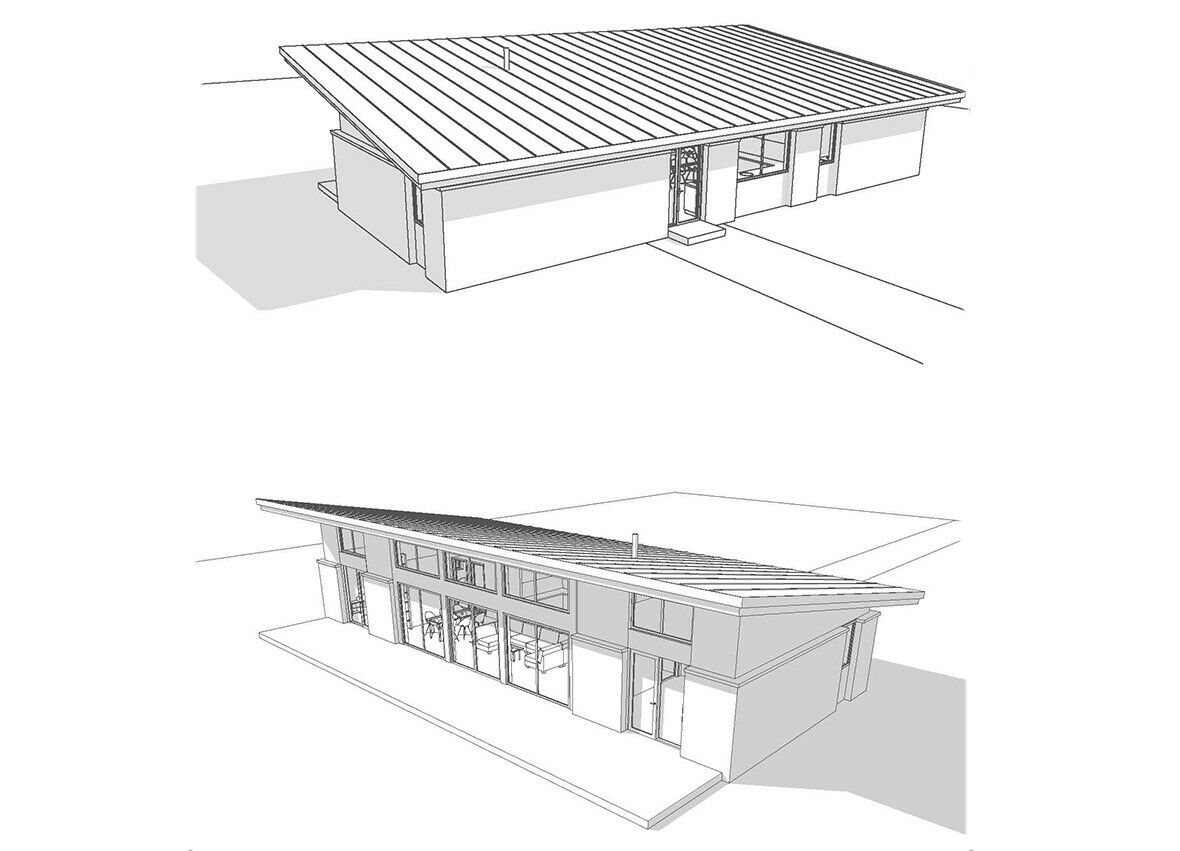

Design: CONTEMPORARY

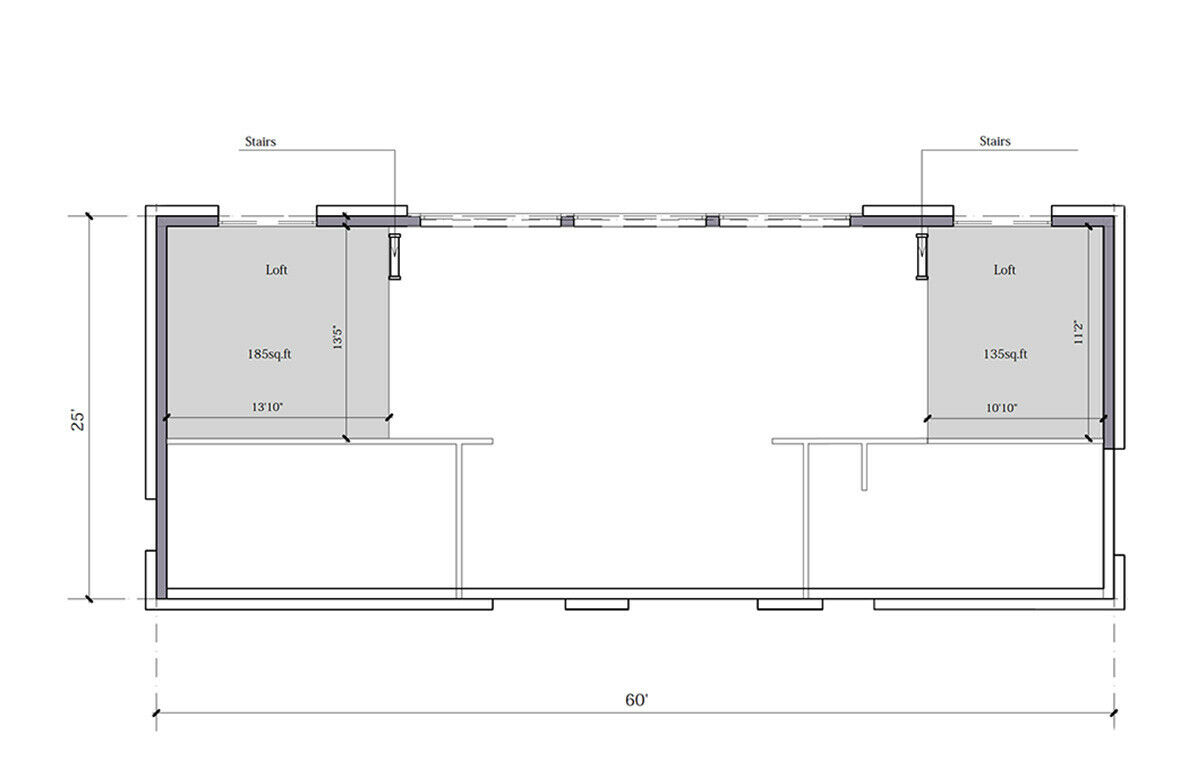

Floors: 2

Gross area: 1650 sq ft (with lofts)

Net area: 1650 sq ft (with lofts)

Bedrooms: 5 (with lofts)

Bathrooms: 2

ECOHOUSEMART “CLT-153”

PREFAB HOUSE KIT INCLUDES THE FOLLOWING SYSTEM MATERIALS ONLY (ITEMS 1-7 BELOW):

1)

Design:

Preliminary Architectural Drawings (unstamped)

**Shop Structural Drawings (unstamped)

Assembly diagram

2)

Cross-laminated timber panels WALL SET

Wood Sill plate offset in the mortar bed - underlying board to install panels onto the foundation - 1 5/8" х 4” (41mm x 100mm)

A set of CLT wall panels (solid timber slabs) for load-bearing external and internal walls - 4” (100mm), pre-cut according to the project documentation, finished quality from inside, industrial-grade on the outside (requires finishing).

Elastic adhesive sealing tape

3)

Roof elements

A set of 4 23/32" (120mm) roof CLT panels, pre-cut according to the design documentation, industrial quality on both sides (requires finishing)

Timber batten (spruce) vertical (Counter battens) - 1 2/3” x 2” (44mm x 50mm)

Timber batten (spruce) horizontal, - ¾” x 4 ¾” (20mm x 120mm)

Roof system - 25/32" х 4 23/32" (20mm x 120mm)

4

)

Frame elements

Interior partition walls framing - 1 5/8" х 4” (41mm x 100mm);

Structural posts – GLT, white Spruce, 7,9" х 7,9” (200mm x 200mm);

5)

Outdoor (exterior) finishing materials

Facade subsystem, battens (spruce), (41mm x 100mm)

Timber ventilation battens for external facades (spruce), (44mm x 50mm)

Veneer for cladding of external walls - white Spruce, T&G ¾” x 7” (19 x 177mm)

6

)

Set of fasteners for the wall structure:

Wedge anchor

Countersunk screw

Rothoblaas HBS8240

Countersunk screw Rothoblaas HBS6120

Galvanized angle bracket WBR09015

Hidden veneer fasteners

Corrugated nails

Post support

ATTENTION!

WE DO NOT SUPPLY ANY OTHER MATERIALS WITH THE ADVERTISED “CLT-153”

KIT IN THIS OFFER!

OPTIONS A) & B) BELOW, OFFERED SEPARATELY FOR AN ADDITIONAL PRICE:

A) Interior finishing materials

Veneer for cladding of internal framed walls - white Spruce, T&G ¾” x 7” (19 x 177mm)

Casing board for windows and doors - planed GLT board 3/4" x 4" (20 x 100mm)

T&G floor board 1,5″. Species – white Spruce

Plinth 1,2" x 1,6"

Ceiling board - T&G, white Spruce 3/4" x 4 3/4" (20 x 121 mm);

Ceiling molding 1" x 1" (if applicable by project)

B) Other

European style double or triple glazed VINYL or wood clad Tilt and Turn windows

Floor joists to cover crawl space or basement

CLT roof panels instead of a roof rafter system are available at an additional cost.

SASHCO coatings and finishes materials. Coatings and finishes should be applied once the building has been enclosed and the CLT has reached moisture equilibrium.

Roof covering materials (Soft shingles, OSB sheathing, Roll waterproofing, Vapor barrier and vapor diffusion membrane)

Drilling holes for concealed wiring

Stamp over the Shop Structural Drawings

IF THIS LISTING IS NOT EXACTLY WHAT YOU REQUIRE, PLEASE CONTACT US FOR A PERSONAL EBAY LISTING FOR YOUR EXACT REQUIREMENTS!

CROSS-LAMINATED TIMBER PRODUCT ADVANTAGES

A distinctive feature of the proposed CLT structure is factory readiness. All CLT panels are made exactly according to the project using advanced CNC woodworking machinery and delivered completely ready for assembly. This allows you to save time and money: you get a technologically advanced solution and fairly simple process of assembly. Construction is easy and fast. The kit can be erected by a small crew within a week's time. CLT panel lifting equipment is required.

When compared to related technologies of construction (concrete, masonry, beams, frame houses), CLT panel technology stands out clear competitive advantages:

Structural

Highly load-bearing building material

Multiple crossed and glued lamellae offer excellent dimensional stability and size accuracy

Outstanding static properties, high seismic resistance

Enables modern architectural shapes due to loads being transferred in two directions

CLT system is structurally comparable to steel and concrete but six times lighter than concrete

Product-specific

Quality-controlled production, continuous internal and external checks

Industrially prefabricated construction elements thanks to CNC timber framing according to plan

The ideal building material for adding storeys due to its specific weight

Planning

High dimensional accuracy due to CNC timber framing

Planning freedom and free floor plans

No limits on individual forms of expression in modern timber construction architecture

More space, relatively small component thicknesses are possible, creating an economic ratio of gross to net floor area.

The ability of exterior panels to be comparable with many facing materials (brick, stone, imitation CLTs, etc.) makes the technology versatile and adaptable to any architectural style.

Ecological

An ecological building material made of renewable raw material

The durable construction method that retains its value

A building product that stores CO2 and produces fewer greenhouse gas emissions during manufacture

Highly efficient production with low primary energy demand

The wood fiber used in CLT is traceable from certified forests

100% environmentally friendly, including the adhesive system

Time-related

Ready-to-assemble trimmed panel components under weather-protected conditions are delivered directly to the construction site.

Large format components minimize the assembly time and hence the construction costs.

Dry construction method, hence rapid erection and soon ready for occupancy

Assembly-friendly

In comparison to concrete structures, CLT projects are installed in a shorter period of time due to the nature of prefabrication and dry materials. This is a crucial advantage, particularly in multi-story buildings.

Detailed pre-construction planning can help to ensure the installation of CLT is easy, safe, and efficient. Many erectors install up to 14,000 sq feet per day with a team of 4-6 people.

Fire resistant

Fire resistance refers to the time during which building elements are able to continue performing their functions despite the presence of a fire. The burning rate of wood structural elements depends on the thickness of CLT panels, the moisture content, and the amount of exposure to fire. Due to its mass, CLT panels char slowly. Once charred, combustion slows and eventually stops. CLT assemblies also have fewer concealed spaces, which reduces a fire’s ability to spread undetected. CLT structures suffer less degradation than concrete and steel structures in a catastrophic fire event.

Seismic resilience

Because of their dimensional stability and rigidity, CLT panels create an effective lateral load resisting system. Researchers have conducted extensive seismic testing on CLT and found panels to perform exceptionally well with no residual deformation, particularly in multi-story applications. In Japan, for example, a seven-story CLT building was tested on the world’s largest shake table. It survived 14 consecutive seismic events with almost no damage. CLT also offers good ductile behavior and energy dissipation.

Cost efficient

Cost efficiencies are achieved through the combination of material and installation costs, and the associated benefits of using a prefabricated system that is structural and architectural

NOTES

:

PRODUCT PICTURES ON THE eBay and SELLER’S WEBSITE MAY BE SLIGHTLY DIFFERENT FROM THE ACTUAL PRODUCTS AND ARE NOT GUARANTEED TO MATCH PERFECTLY THE ACTUAL PRODUCTS.

THIS CLT HOUSE KIT IS MADE OF HIGH-QUALITY NORTHERN WHITE SPRUCE, EASY PROFESSIONAL ASSEMBLY TO BE ORGANAIZED BY BUYER.

YOU ARE BUYING ONLY THE PREFABRICATED CLT KIT NON PAINTED, OR STAINED, IN WOOD NATURAL COLOR. PLEASE READ ABOVE WHAT IS INCLUDED IN THE KIT. NO LABOR OR ANY OTHER MATERIALS ARE INCLUDED!

THIS KIT DOES NOT INCLUDE WINDOWS, DOORS, PLUMBING, ELECTRICAL, FIXTURES SUCH AS TOILETS SINKS OR CABINETS.

CONCRETE, ERECTION, INTERIOR FINISHING, ROOF INSULATION, STAIRWAY, PLUMBING, HVAC, ELECTRICAL ARE TO BE PAID BY BUYER SEPARATELY TO LOCAL SUPPLIERS

ALL PERMITS AND RELATED FEES ARE PURCHASER’S RESPONSIBILITY.

THE BUYER IS RESPONSIBLE TO MEET THE BUILDING PERMITS AND REQUIREMENTS IN THEIR STATE/COUNTY. SO PLEASE CHECK AT YOUR COUNTY BUILDING DEPARTMENT OFFICE TO FIND OUT WHAT IS REQUIRED.

CUSTOMERS AGREE TO HOLD ECOHOUSEMART AND ANY AUTHORIZED DEALERS FREE OF ANY LIABILITY FOR IMPROPER INSTALLATION, MAINTENANCE, AND REPAIR OF ANY ECOHOUSEMART PRODUCTS.

WE WILL BE GLAD TO GIVE YOU A FREE PRICE QUOTE ON YOUR CUSTOM HOUSE INQUIRY.

MANUFACTURING IS CUSTOM, AND ORDERS TAKE GENERALLY UP TO 150 DAYS TO RECEIVE SINCE THE CUSTOMER APPROVES THE STRUCTURAL DRAWINGS.

PAYMENT: BY PAYPAL UNLESS OTHER ARRANGEMENTS ARE MADE PRIOR TO PURCHASE.

HOUSE KIT MANUFACTURING WILL NOT BEGIN UNTIL THE FULL PAYMENT CONDITIONS ARE MET.

CONSTRUCTION COMPONENTS DIRECTLY EXPOSED TO WEATHERING MUST BE FACED WITH EFFECTIVE WEATHER PROTECTION.

SHIPPING: FREIGHT WILL BE PAID BY THE BUYER. CONTACT US TO GET A SHIPPING QUOTE TO YOUR LOCATION IN ADVANCE.

YOU CAN ARRANGE YOUR OWN PICK UP FROM THE WAREHOUSE IN JERSEY CITY, NJ 07305

PRIOR TO PURCHASE:

Construction experience is required to assemble this building package. It is recommended that a professional contractor be hired to install the kit if the purchaser is not qualified.

Check with your local building official or Code Enforcement Office to obtain necessary permits and review possible site zoning, foundation, and building requirements or restrictions (including, but not limited to: frost depth, soil-bearing pressure, drainage, etc.).

Ensure that the building requirements meet the specifications of the building package kit (wind, seismic, snow load, exposure, etc.).

In some cases, engineering criteria required for your build site may warrant a building plan different from the standard.

ECOHOUSEMART

will work with your licensed local architect to provide a suitable solution for your zoning requirements.

LOGISTICS AND PACKAGING:

The elements are delivered directly to the construction site in a container for self-collection. Freight will be paid by the buyer separately. Please contact us to get a shipping quote to your location in advance.

Our products are well shop-packed, which ensures the preservation of details during loading and unloading, transportation.

The transportation package is compiled of details of the same section area and length.

AT

ECOHOUSEMART

WE WILL CUSTOMIZE OUR KITS TO FIT YOUR INDIVIDUAL PLANS, WISHES, AND DREAMS.

WE ARE LOOKING FOR TALENTED DESIGNERS, BUILDERS AND NEW DEALERS THROUGHOUT THE US.

LOOKING FORWARD TO HEARING FROM YOU, AND HAVE A GREAT DAY!

ECOHOUSEMART

View more great items