-40%

MOON HOUSE 20’ DIAM DOME FRAMING KIT PREFAB WOOD PRE-CUT DIY HOME FRAME A~330 SF

$ 3162.72

- Description

- Size Guide

Description

PLEASE READ THE COMPLETE DESCRIPTION CAREFULLY PRIOR TO BIDDINGTHIS IS NOT A COMPLETE HOUSE. YOU ARE BUYING A DOME FRAMING KIT ONLY.

LABOR IS NOT INCLUDED.

THIS ITEM IS NOT IN STOCK AND WILL BE MADE TO ORDER UPON THE PURCHASE. LEAD TIME TO FABRICATE AND DELIVER THE KIT IS 120-150 DAYS.

DRAWINGS ARE NOT INCLUDED AND MAY BE PRODUCED AT ADDITIONAL COST.

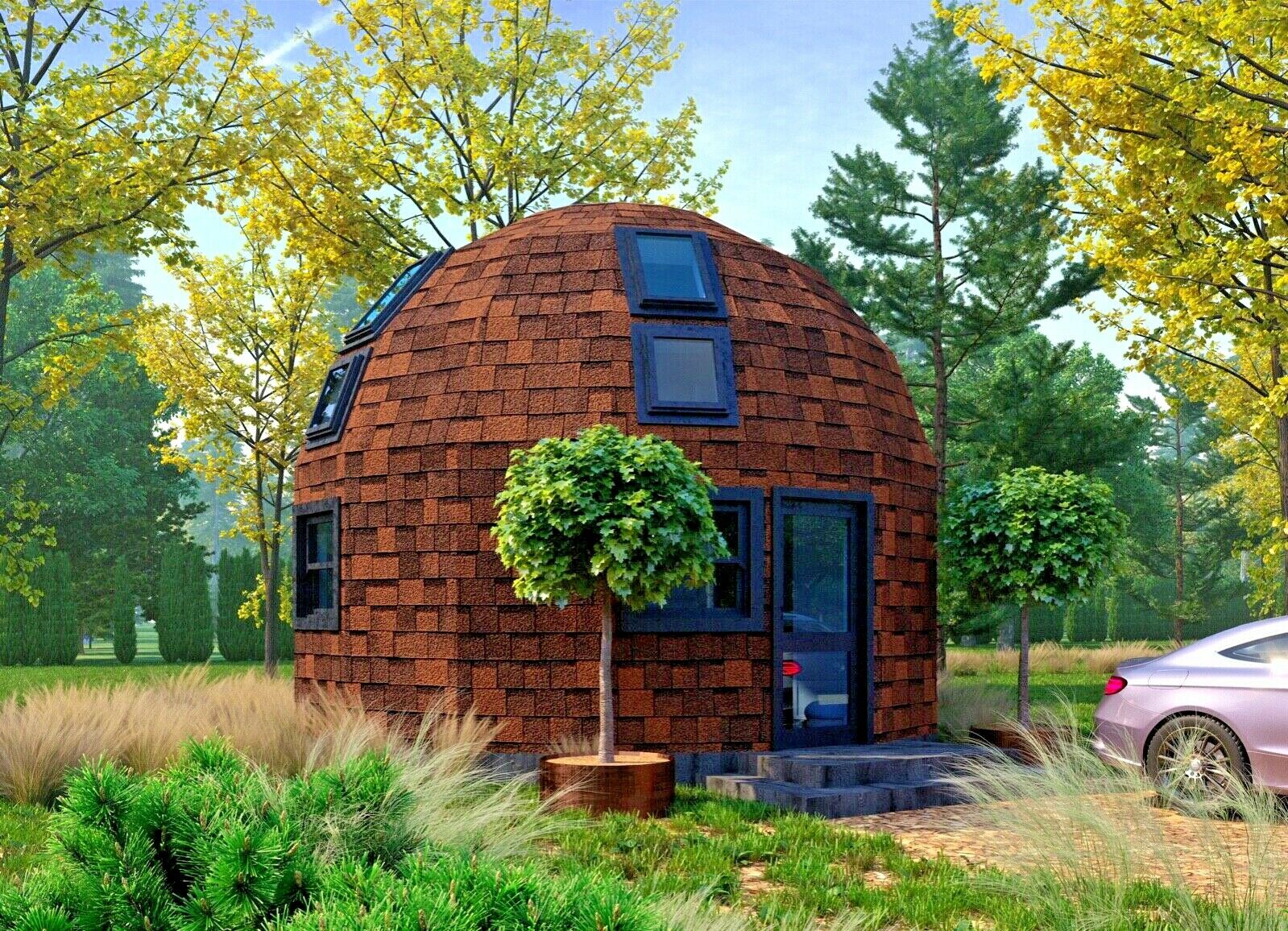

Moon House D20 strut framing kit for a DIY dome house with patented wooden joints.

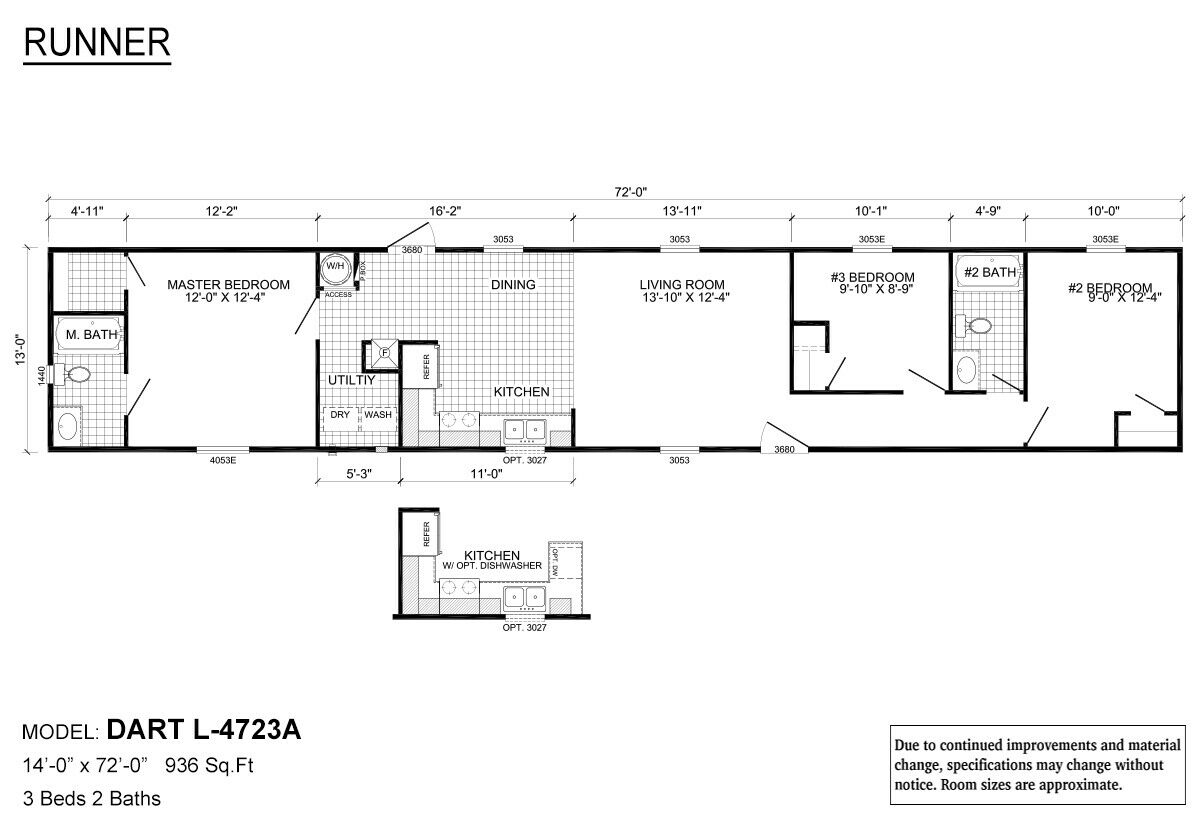

Moon House D20

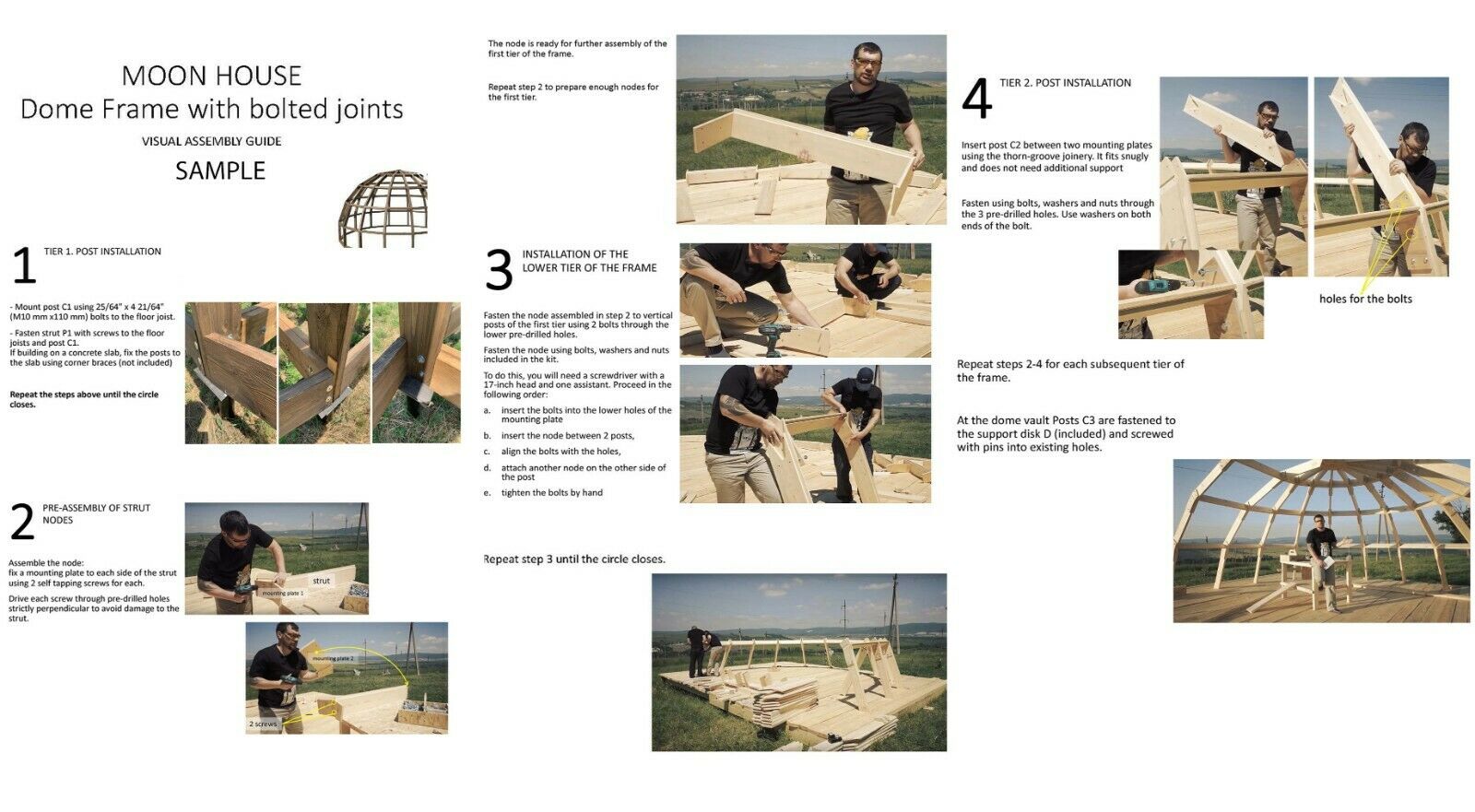

is a ready-made dome house strut framing kit, diameter 20 ft, which can be assembled by 1-2 person using the assembly manual provided. The Moon House D20 with its bolt-locking joint type is patented. The dome is self-supporting, so the interior can be arranged completely freely according to your wishes.

Ease of Assembly Without Skilled Labor or Heavy-lift Equipment

— All wooden components of the dome strut framing kit are pre-cut and pre-drilled to exact specifications to make it easy for unskilled people to assemble them with precision and confidence. One person can complete the framework in about one or two days. No special tools or expensive lift-equipment, like cranes or forklifts, are necessary to load, handle, or assemble an EcoHouseMart strut framing kit.

MOON HOUSE D20 STRUT FRAMING KIT CHARACTERISTICS:

The frame kit is made of kiln-dried solid wood. Species - Spruce or Pine

The dome is a self-bearing, that’s why you make any layout in a house.

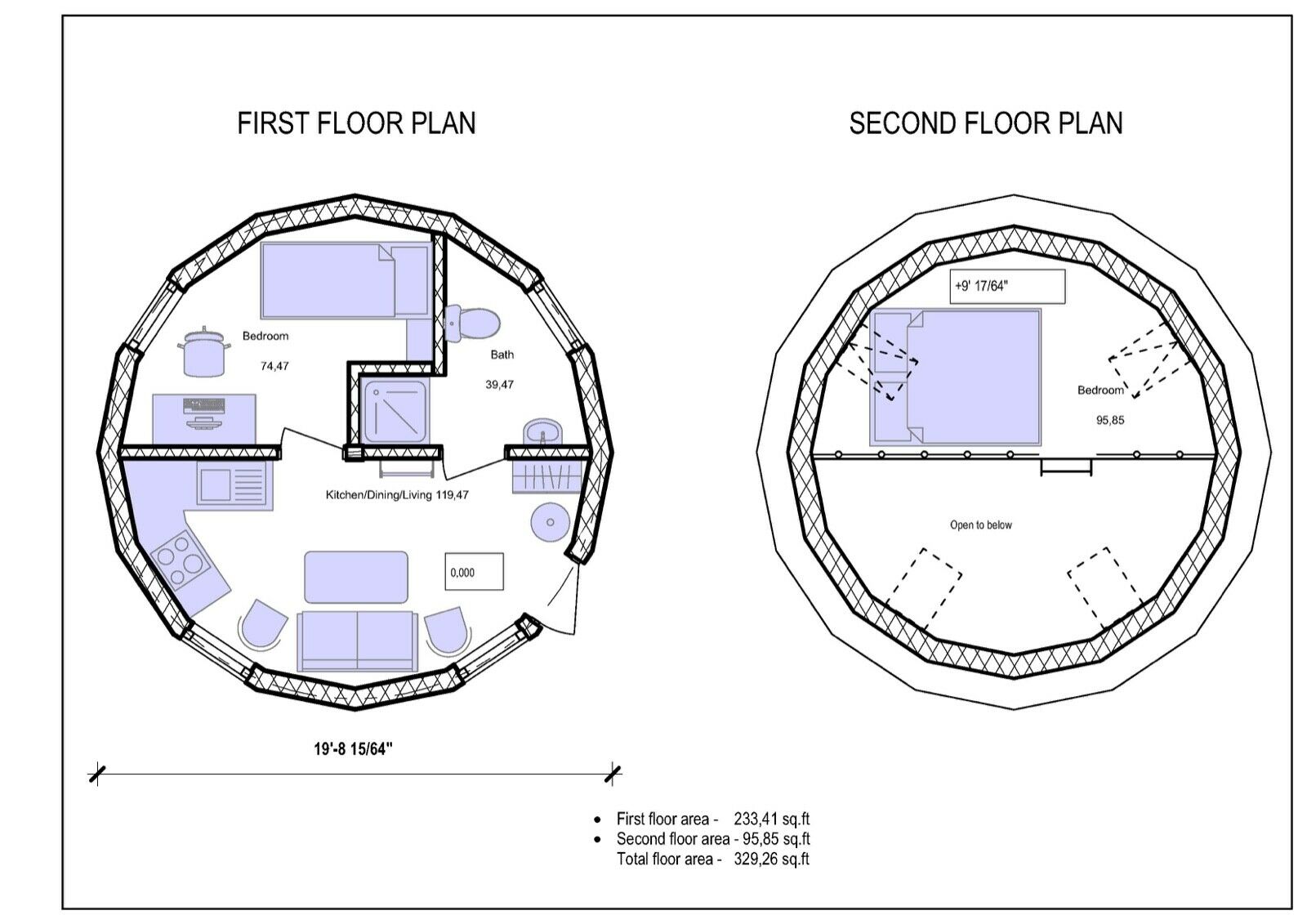

The frame is pre-sized for 2 floors. One can easily make an installation of the loft as an additional space if desired.

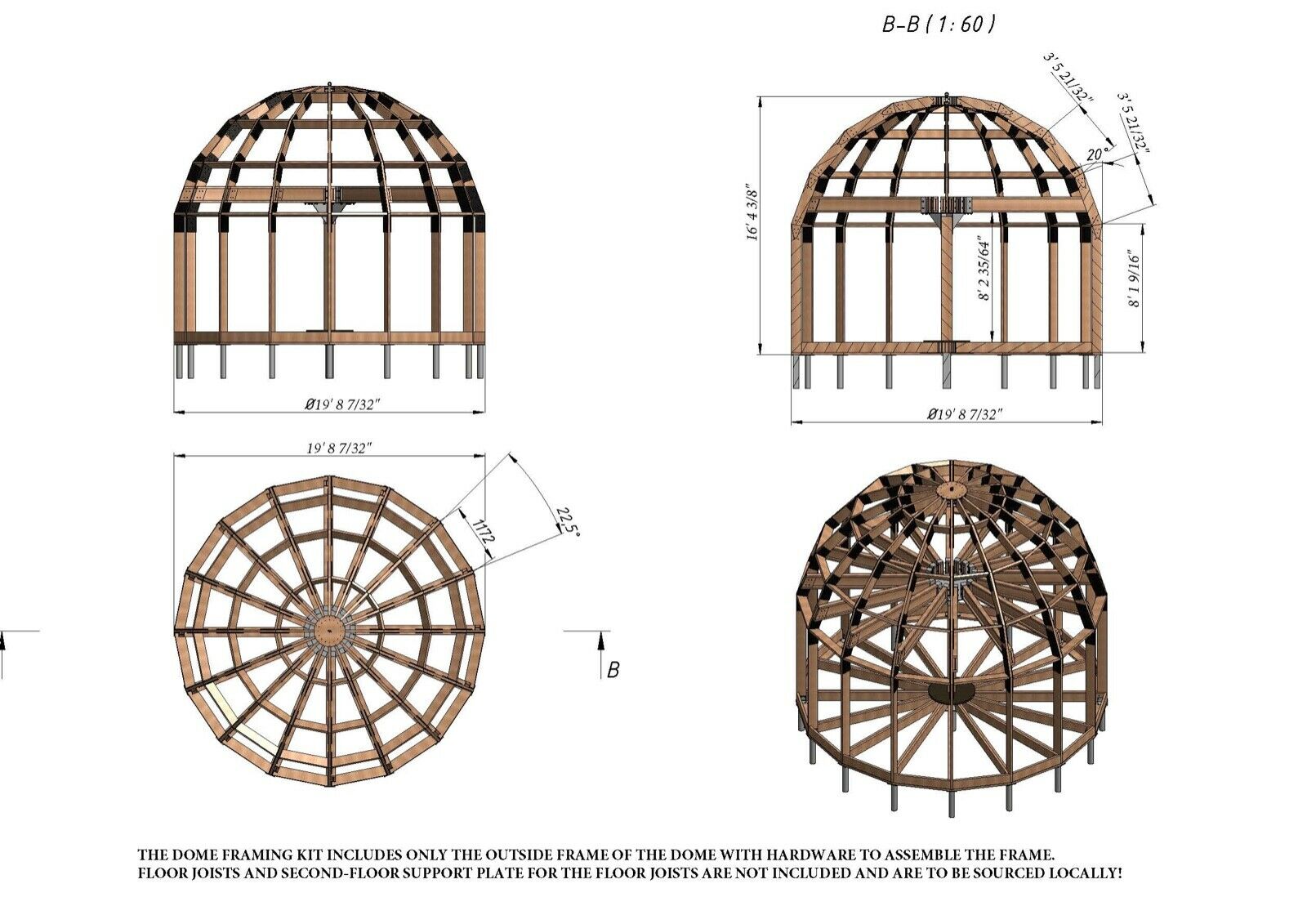

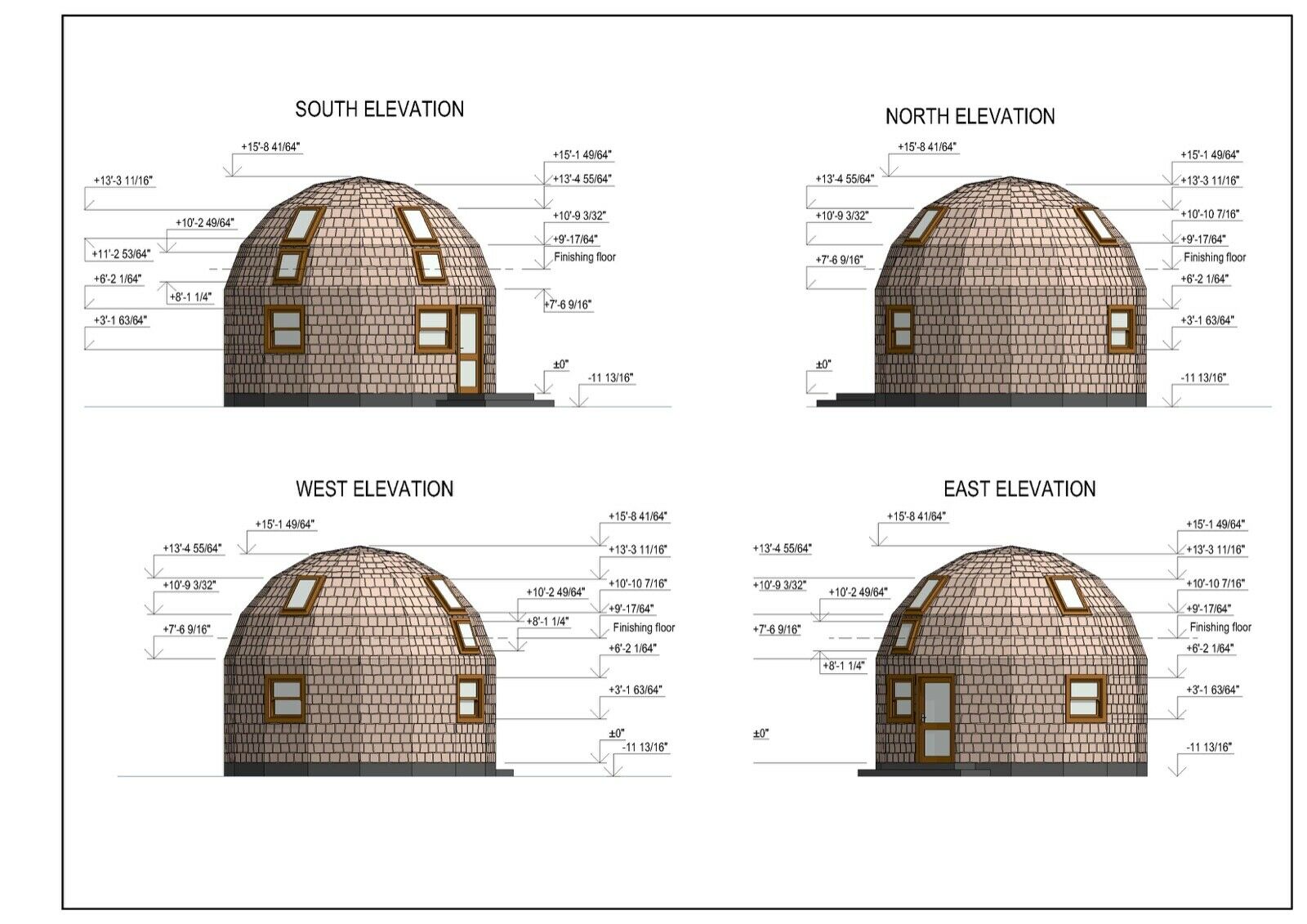

Height - 15' 3” (4.7 m)

Diameter: 20' (6 m)

Total roof surface area 915 sq.ft (85 m2)

First floor area: 234 sq.ft

Second floor LOFT area as advertised on the floor plan: 96 sq.ft.

Total floor area as advertised with the loft floor: 330 sq.ft

MOON HOUSE D20 STRUT FRAMING KIT INCLUDES:

Precut and predrilled 2" x 8” struts. Exact size - 1 3/4" x 7 3/4" (45 mm х 195 mm)

.

All struts of the frame are made from kiln-dried select structural Spruce, which can withstand considerable compression and tension. We do not use automatic feeds or gang drills. All struts are individually cut and drilled at precise angles. In addition to purchasing lumber that is graded and rated for strength, we personally inspect each piece for knots or warping. You get only top quality struts that are accurately pre-cut, pre-drilled, and coded.

Easy to Read Assembly Manual.

Templates for cutting of OSB panel sheathing.

Weight of the Moon House D20 framing kit: 3,306 pounds (1,5 tons), volume - 100 ft3 (3 m3)

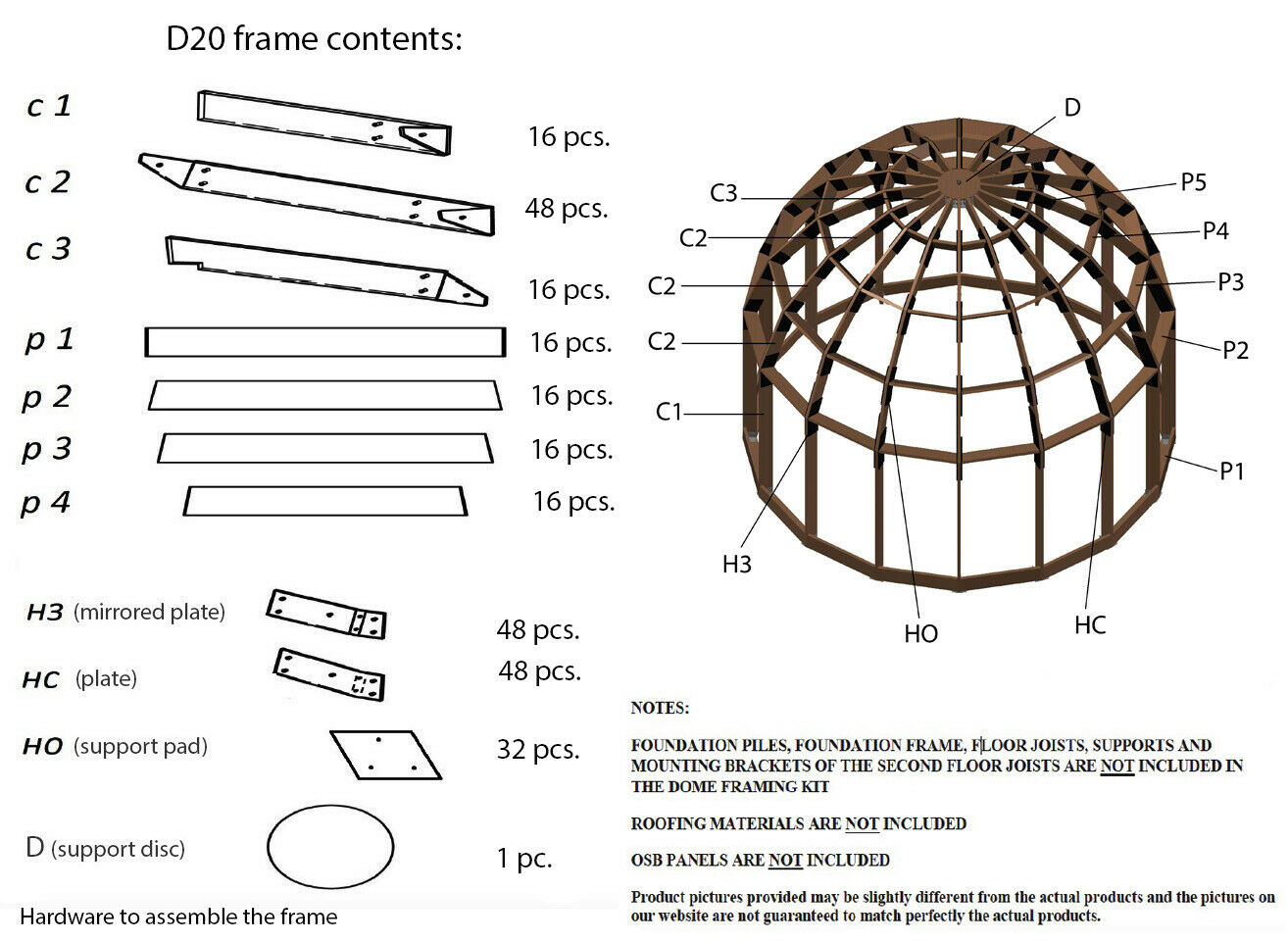

MH-D20 DOME FRAME CONTENTS

Name

Quantity

Posts (CNC pre-cut)

1

С-1

16 pcs.

2

С-2

48 pcs.

3

С-3

16 pcs.

Struts (CNC pre-cut)

4

Р-1

16 pcs.

5

Р-2

16 pcs.

6

Р-3

16 pcs.

7

Р-4

16 pcs.

8

Р-5

16 pcs.

Mounting plates (CNC pre-cut)

9

НЗ

64 pcs.

10

НС

64 pcs.

11

НО

32 pcs.

12

Support disk

1 pc.

Hardware to assemble the frame

THE LISTING INCLUDES THE DOME STRUT FRAMING KIT ONLY.

For finishing of the frame, OSB board should be purchased separately and sawn according to the installation sequence, provided with the structure. Approximate quantity of OSB panels (dimensions: 23/32” х 4’ 1 7/32" x 8' 2 27/64") to cover the frame from outside is 38 pcs. NOT INCLUDED in the price of the kit! To complete the basic dome shell, OSB panels (to be purchased locally) need to be pre-cut and nailed to the framing kit during frame installation.

The floor joists are to be made of standard 2” x 8” (50 × 200 mm), which is NOT INCLUDED in the price of the kit!

The coded framing parts are cut and drilled for precision fit. They are easy to identify, and they fit the way the instructions say they should. We guarantee it.

WE DO NOT SUPPLY ANY OTHER MATERIALS WITH THE DOME STRUT FRAME KIT IN THIS LISTING!!!

A distinctive feature of the EcoHouseMart dome frame structure is factory readiness. This eliminates the need to create blanks, fitting them to each other. All parts of the frame are made exactly according to the project using advanced woodworking machinery and delivered completely ready for assembly. This allows the customer to save time and money: you get a technologically advanced solution and fairly simple process of assembly. Construction is easy and fast. The frame can be erected by two people in about two days.

The delivery set includes the dome frame kit only with step by step assembly manual. OSB panels for sheathing and floor joists are not included in this listing and to be purchased locally before assembly. OSB is to be cut using the templates provided in the assembly manual. Estimated time - 1 day.

You can assemble the dome any time of the year.

ADDITIONAL MATERIAL TO BE PURCHASED SEPARATELY:

Frame

Interior wall finish: OSB, drywall or T&G board, or other interior finishing material of your choice

Vapor barrier

Spray insulation or mineral wool insulation

Windproof barrier

Exterior sheathing: OSB panels (23/32” х 4’ 1 7/32" x 8' 2 27/64") to cover the frame from outside (approximately 36 OSB panels, to be cut according to provided templates)

Soft shingles to cover the dome

Floors and ceilings

Floor joists for 1 and 2 floors

Stopper bar - sawn block

Subfloor - OSB or sawn block

Windproof barrier

Spray insulation or stone wool insulation

Vapor barrier

Floor finishing: OSB or T&G floorboard, or other floor finishing material as you desire

First floor ceilings finishing: OSB, drywall or T&G board, or other interior finishing material of your choice

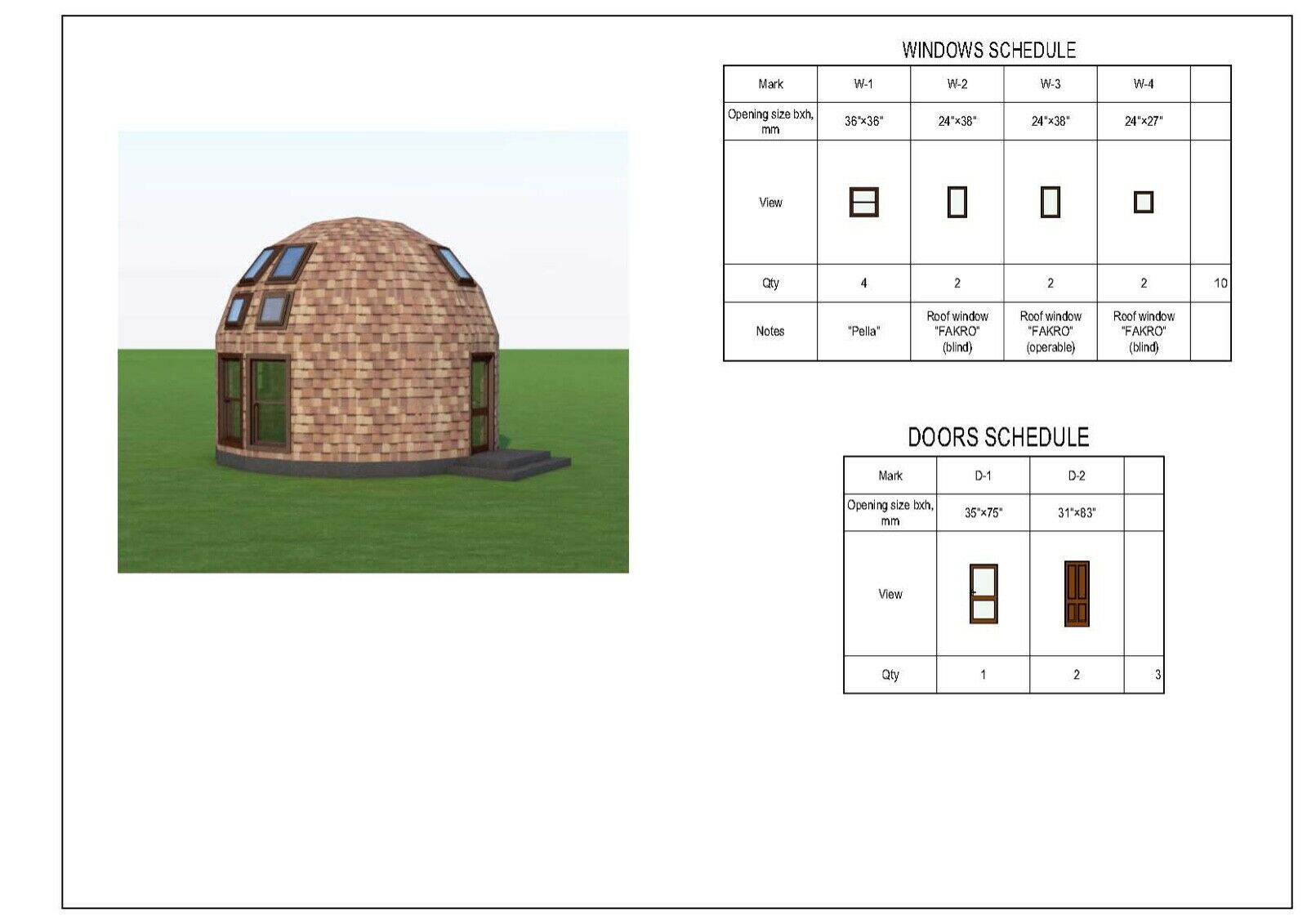

Windows and doors

First floor - regular windows

Second floor - roof windows/skylights

Front door and interior doors

Casing board for windows and doors

Stairs for the loft (optional if desired to be build)

Fasteners:

Roofing nails

Self-tapping galvanized screws

Corners, bolts, washers, and nuts for fixing frame, floor joists, and frame to the foundation

Additionally:

Foundation (screw piles as an option, or any other recommended by your local engineer)

Electrical

HVAC and heating system

Water supply and sewerage

Fixtures such as toilets sinks or cabinets

WHY CHOOSE DOME HOMES? HERE ARE JUST A FEW REASONS:

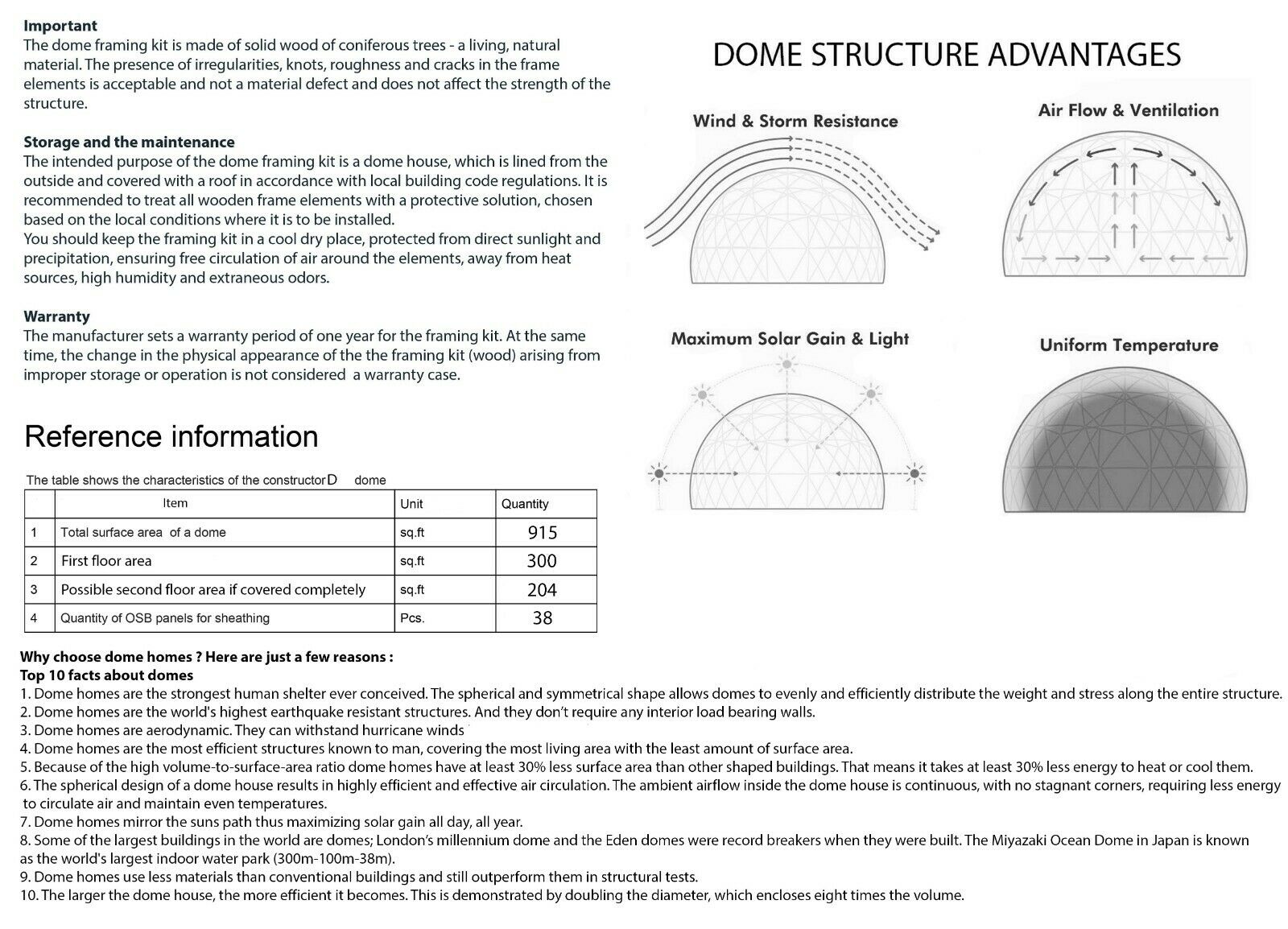

The spherical design results in highly efficient and effective air circulation in both summer and winter. Less surface area makes the dome house less susceptible to temperature changes, and thus, inexpensive to heat and cool as compared to conventional, rectangular homes. The aerodynamic exterior means that cold and warm air flows around the dome house instead of forcing its way into the interior. The dome homes mirror the suns path thus maximizing solar gain all day, all year and they also distribute perfectly heat and sounds. There are two reasons why dome homes are energy efficient: The ambient airflow inside the dome house is continuous, with no stagnant corners, requiring less energy to circulate air and maintain even temperatures. The energy required to heat and cool a dome house is approximately 30% less than a conventional building. The second is the high volume-to-surface-area ratio, requiring less building materials to enclose more space. The lower the ratio of a building’s outside perimeter to its enclosed living area, the less energy is required for building, heating and cooling. The sphere has 25% less surface area per volume enclosed than any other shape. The dome house combines the inherent stability with the advantageous volume-to-surface-area ratio of a sphere. The larger the dome house, the more efficient it becomes. This is demonstrated by doubling the diameter, which encloses eight times the volume. Given the inverted circular design of the dome house, the dissipation of energy is also carried out in a highly efficient manner. This means that the various sections of such a dome house can be rapidly heated and cooled in an even manner. Dome homes offer the best structural integrity when compared to other styles of construction. This is perhaps why they have been in use since the ancient times, when building stronger and long lasting structures was a priority. The above features of dome buildings have become widely accepted in the modern construction industry and have revived the trend of such structures making them the best option for futuristic and modern architecture.

MOST COMMONLY ASKED QUESTIONS:

Why do dome structures save on building materials?

The primary factor affecting the efficient use of materials and energy in the structure is its shape. Think of a soap bubble. A sphere represents the smallest amount of material surface area needed to enclose a given volume of space. A divided sphere becomes one of the most efficient shapes known to enclose a given floor area.

Why are dome structures so strong?

The nature of the spherical design provides strength because the stress is shared evenly by all the points of the structure. The dome shape allows environmental stress such as movement from an earthquake or wind or stress from snow loading to be evenly distributed throughout the structure. The geometry of the triangle offers additional strength to the dome shape.

Why do dome structures conserve less energy for heating and cooling?

The answer again lies in the shape of the dome structure. The lower the total outside surface area (walls and ceilings) the greater the efficiency in energy use for heating and cooling. A dome has approximately one-third less surface area to the outside than a box-style structure. The amount of surface area exposed to the elements has a much greater impact on energy efficiency than insulation values. Additionally, heat loss from the foundation of a home is generally more dependent on perimeter length than the floor area. A dome, having a smaller perimeter/square footage ratio than a box-style home, will lose less heat from the foundation.

Efficient airflow inside that dome adds to the energy savings further; the curved surface of a dome provides a natural circulation of internal air. Outside the dome, the shape of the dome provides an aerodynamic effect; the wind passes over the dome with less resistance. In comparison, a box-style structure provides a flat barrier to wind, creating positive wind pressure with air infiltration on one side, and suction, or negative wind pressure, with internal air exfiltration, on the opposite external surface.

What other advantages do dome structures offer over conventional structures?

Interior advantages of the dome include greater freedom of floor plan design, cathedral ceilings, evenness of light, heat, and sound distribution. Domes display superior light characteristics as spherical shapes tend to amplify light while rectangular shapes tend to absorb light; in many cases, it is actually brighter inside a dome without any interior lights turned on than it is outside. Acoustical advantages include more even sound distribution and approximately 30% less outside noise infiltration.

What kind of foundations can be used with the dome kits?

The type of foundation best suited for your home is determined by the terrain of the land, the type of soil, and local building codes. The foundation of a dome differs only in shape from that of a conventional house. We offer standard foundation plans on piles.

What kind of roofing does EcoHouseMart recommend?

Asphalt shingles are the most common roofing material as it is easy to work with and very attractive. You could purchase shingles in a variety of colors and textures and it is the most affordable choice. Other options include wood shingles, metal shingles, and spray on roofs.

What kind of insulation is recommended?

Standard insulation material is used. The most common choices are fiberglass or rigid foam. EcoHouseMart’s 2" x 8” framing members allow for 7 1/2" of insulation, sufficient for most climatic conditions. Other options include spray-in expanding foam which is very effective.

What about venting the insulation to prevent condensation?

Condensation can form in a cavity when there is air in that cavity. Moisture enters on the air and if there is an air space the air must be circulated to prevent moisture from building up. That is why attics are vented in box type houses. However, if the cavity is filled with a material that displaces the air, condensation is not a problem. That is why vertical walls on box type houses are not vented. They are filled with insulation.

The same applies to our domes. The walls are 2" x 8” and are filled with insulation. By using an expanding spray foam insulation, it seals up the dome so well that no interior vapor barrier is needed.

What options do I have for windows?

There are many choices in window design and selection available for a dome home.

The first option is the skylights. Individually or clustered, skylights maximize the usable space in any panel. Skylights maintain the graceful shape and highlight the unique architectural structure of a dome.

Standard, conventional windows can be used in a dome when they are framed upright in the lower sections of a dome, or in a dormer. Conventional windows are generally less expensive than skylights.

A third option is conventional shaped windows that are specially designed for use in a sloping roof. These can be readily adapted for use in a dome home. We are happy to recommend sources of specialty windows to meet your individual needs.

What kinds of interior finishing materials can I use?

You can use any standard interior finishing material such as drywall or wood paneling.

What kinds of heating, cooling, and air ventilation systems can I use?

Domes employ traditional heat and air conditioning, whether it be forced air, electric baseboard, or in-floor radiant heat. The plumbing, mechanical and electrical systems of a dome dome are no different than that of a conventional structure.

How do I find a contractor who will work with dome?

Any licensed general contractor should be able to do the work.

Can I put together the dome shell myself?

Yes. All wooden components of the EcoHouseMart Dome frame are pre-cut and pre-drilled to exacting specifications and coded to make it easy for unskilled people to assemble them with precision and confidence. The largest piece of a 20' diameter dome is a 7ft. long 2" x 8”, which is easily handled by one person. Over 90% of our customers erect their dome shell themselves.

What equipment will I need?

The only tools you will need are hammers, ladders, rolling scaffolding (desirable), and nail guns (desirable). EcoHouseMart Domes are completely free-standing during construction. No shoring up is needed. No special tools or expensive equipment, like cranes or forklifts, are necessary to assemble an EcoHouseMart Dome.

IF THIS LISTING IS NOT EXACTLY WHAT YOU REQUIRE, PLEASE WRITE TO US FOR A PERSONAL EBAY LISTING FOR YOUR EXACT REQUIREMENTS!

WE CAN SUPPLY DIFFERENT FRAME SIZES FOR THE DOME, AS WELL AS DIFFERENT HEIGHTS. PLEASE REQUEST A QUOTE FOR THE FOLLOWING DOME DIAMETERS: 13FT, 20 FT, 26FT, 33FT, 40FT, 46FT.

NOTES:

THIS DOME FRAME KIT IS MADE OF NORTHERN WHITE SPRUCE, EASY-TO ASSEMBLE.

YOU ARE BUYING ONLY THE PREFABRICATED FRAME KIT. NO LABOR OR ANY OTHER MATERIALS INCLUDED!

THIS FRAME KIT DOES NOT INCLUDE WALL FILLINGS, WINDOWS, DOORS, PLUMBING, ELECTRICAL, FIXTURES SUCH AS TOILETS SINKS OR CABINETS.

ALL PERMITS AND RELATED FEES ARE PURCHASER’S RESPONSIBILITY.

CONCRETE, ERECTION, INTERIOR FINISHING, ROOF INSULATION AND COVERING, STAIRWAY, PLUMBING, HVAC, ELECTRICAL ARE TO BE PAID BY BUYER SEPARATELY TO LOCAL SUPPLIERS

THE BUYER IS RESPONSIBLE TO MEET THE BUILDING PERMITS AND REQUIREMENTS IN THEIR STATE/COUNTY. SO PLEASE CHECK AT YOUR COUNTY BUILDING DEPARTMENT OFFICE TO FIND OUT WHAT IS REQUIRED.

CUSTOMERS AGREE TO HOLD ECOHOUSEMART AND ANY AUTHORIZED DEALERS FREE OF ANY LIABILITY FOR IMPROPER INSTALLATION, MAINTENANCE, AND REPAIR OF ANY ECOHOUSEMART PRODUCTS.

MANUFACTURING IS CUSTOM AND ORDERS TAKE GENERALLY 120 TO 150 DAYS TO RECEIVE.

HOUSE KIT MANUFACTURING WILL NOT BEGIN UNTIL THE FULL PAYMENT CONDITIONS ARE MET.

PAYMENT:

BY PAYPAL UNLESS OTHER ARRANGEMENTS ARE MADE PRIOR TO PURCHASE.

SHIPPING:

FREIGHT WILL BE PAID BY THE SELLER WITHIN CONTINENTAL USA. CONTACT US TO GET A QUOTE ON SHIPPING OUTSIDE THE USA.

YOU CAN ARRANGE YOUR OWN PICK UP FROM THE WAREHOUSE IN JERSEY CITY, NJ 07305

PRIOR TO PURCHASE:

Check with your local building official or Code Enforcement Office to obtain necessary permits and review possible site zoning, foundation, and building requirements or restrictions (including, but not limited to: frost depth, soil-bearing pressure, drainage, etc.).

Ensure that the building requirements meet the specifications of the building package kit (wind, seismic, snow load, exposure, etc.).

In some cases, engineering criteria required for your build site may warrant a building plan different from the standard.

LOGISTICS AND PACKAGING:

Our products are well shop-packed, which ensures the preservation of details during loading and unloading, transportation, and storage.

Transportation packages are wrapped from 6 sides in waterproof polyethylene packing tape.

Transport characteristics: Weight of the Moon House D20 framing kit is 3,306 pounds (1,5 tons), volume - 95 ft3 (2.7 m3). It is packed on pallets in the package. It may be loaded on by one person.

WE CAN SUPPLY DIFFERENT FRAME SIZES FOR THE DOME, AS WELL AS DIFFERENT HEIGHTS. PLEASE REQUEST A QUOTE FOR THE FOLLOWING DOME DIAMETERS: 13FT, 20 FT, 26FT, 33FT, 40FT, 45FT.

WE ARE LOOKING FOR TALENTED DESIGNERS, BUILDERS AND NEW DEALERS THROUGHOUT THE US.

THANK YOU FOR YOUR INTEREST IN ECOHOUSEMART PRODUCTS! LOOKING FORWARD TO HEARING FROM YOU!

ECOHOUSEMART

View more great items